|

□

|

|

□

-

-

-

-

- s

-

-

-

- -

|

|

□

|

|

|

|

Products

|

Filter

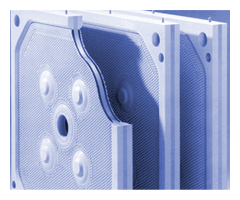

Plates

Polypropylene - Recessed, Membrane, Replaceable membrane and Plate &

Frame designs are standard supply for Filter Pure. Special custom designs

are also manufactured and are produced for special applications.

Other products include Disc Sectors (Polypropylene

& Stainless Steel) Moore Leaf and Electrolytic Cells.

Filter Plates for Filter Presses

Standard

and custom designs to suit your liquid-solid separation

needs.

Filter Pure has a full range of

Filter Plates

for solid-liquid separation, as well as accessories for all

industries, including Mining, Industrial, Chemical and

Waste Water Treatment.

|

|

|

Recessed

Filter Plates Accommodates

any brand of filter!

Plate and Frame

Plate and Frame are a predecessor to

Recessed Plates. The

chamber is formed by a flat plate on each side of a frame. Cake

is collected in the frame. This type of plate is usually used

for polishing applications when filtration area is more

important

than volume.

Our Recessed Plates are designed for 7, 15, and 20 bar operation

(100/225/300psi). They are available for sidebar or overhead

press designs. Mounting hangers or side handles can accommodate

any brand of filter.

There are 3 basic types of Recessed Plates; Open

Filtrate, Closed Filtrate

and Gasketted

Recess Plate - Open Filtrate

Gasketted Recess

Plate

Recess Plate - Open Filtrate

Recess Plate - Open Filtrate:

An Open Filtrate Recess Plate, discharges filtrate on one side of the plate or via

vertical holes along the underside of the Filter Plate.

Recess Plate - Closed Filtrate:

Virtually identical to the open filtrate but with the

addition of corner pads. Holes in these corners form a pipe or

tube and collect the filtrate, which is discharged to a manifold

at the feed end of the Filter Press. Spigots may be used to

examine the filtrate externally.

Gasketted

Recess Plate:

Grooves

containing 'O' ring around the sealing edge and filtrate holes

form a tight seal when the Plate Pack is closed in combination

with Filter Cloths.

Plate patterns come in 3 distinct drainage patterns; pipped, elongated

pip and grooved. The pipped design is more common on Press

Plates. This design provides better support for Filter Cloth, allowing

filtrate to discharge along the base of the plate with the least

resistance

Fixed

and Replaceable Membrane Plates

Fixed and

Replaceable Membrane Plates

are available. Membrane

Filter Press Plates have a chamber below the drainage surface

that may be inflated. The common method used is water pressure,

which is generated by pumping into the squeeze cavity to inflate

the face of the plate against the Filter Cake. Air may also be

used.

Membrane Plates are used to reduce the cake moisture

content or shorten the filtration cycle time. Two types of

Membrane Plate designs are used; Fixed and Replaceable. Mixed

pack Membranes are the most common configuration (one Recessed

Plate then one Membrane Plate alternate in the press plate

pack). The final product produces savings in the overall plate

pack cost.

Membrane Plates usually operate at a feed pressure of up to 7

bar and squeeze pressure to 15 bar.

Fixed Membranes is manufactured by moulding a membrane

face and a core plate separately. The face is then joined into

the core by heat welding to form a homogeneous plate. Although

this type of membrane is suitable for many designs, it has

particular advantages in food applications where the lack of

joints will prevent contamination.

Replaceable Membranes use a Polypropylene core, which is

machined to accept the connection and seal of a rubber membrane.

These faces are easily changed. EPDM Thermoplastic and other are

used for specific conditions. Savings in operations can be

achieved in difficult environments, and the membrane's superior

flexibility make it the best design for many installations.

These replacement type Membranes are used extensively in the

Brewery Industries.

|

|

|

|

|

|

|

|

|

|

|

|